tests for hardness|types of hardness testing methods : importer Tests for indentation hardness are primarily used in engineering and metallurgy. The tests work on the basic premise of measuring the critical dimensions of an indentation left by a . Beto Coimbra is on Facebook. Join Facebook to connect with Beto Coimbra and others you may know. Facebook gives people the power to share and makes the world more open and connected.

{plog:ftitle_list}

web17 de out. de 2023 · Double Down, pictured Monday, Oct. 16, 2023, is a new sports bar, grill and casino opening soon at 3165 33rd St. S., in Fargo.

Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for .Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).

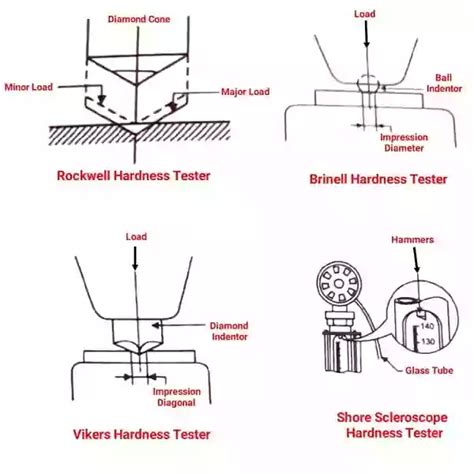

Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. In this article we shall explore five of the most common test methods for measuring the hardness of .

рубанков нет влагомер

Tests for indentation hardness are primarily used in engineering and metallurgy. The tests work on the basic premise of measuring the critical dimensions of an indentation left by a . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.Hardness Testing Basics. Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics. By: Rich . Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing .

There are several different tests used to display the hardness of materials including, Brinell (HB), Rockwell (HRC), Vickers (HV)and Leeb. Rockwell tends to be the most commonly used way of testing hardness, due to its speed and .

types of hardness testing methods

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. To avoid the adverse effects of hard water, the calcium and magnesium mineral content in the water should be below 60 mg/L. The USGS standards for water hardness levels are as follows: Soft water: 0 to 60 mg/L; .

The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop .Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf.

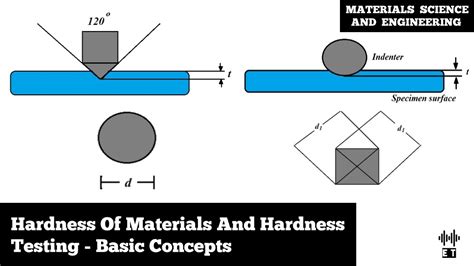

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Water hardness test meters detect the number of solids dissolved in your water. Find the “On” button near the meter’s display and press it down for a few seconds. After 2-3 seconds, the display will light up and read “0.0” so you can start using the meter.The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring the

Hardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method.

The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness . In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. But in layman's terms, you may notice water hardness when your hands still feel slimy after washing with soap and water, or when your drinking glasses at home become less than crystal clear. Learn a lot more about water hardness on the Water Science . Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing.

Brinell Hardness Test. You might have heard about this in school, that you can get a ball bearing, whack it with a hammer on a piece of metal with a known hardness, then whack it on the piece of metal in question, compare the diameters of the indents, and work out the hardness of the metal from the results. . Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness .

рфьф влагомер

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface . Opt for a kit made by a reputable water-testing manufacturer, ensuring the kit tests for hardness. Some kits test only for specific contaminants, like radon, while others test for overall quality and safety. Testing kits differ slightly. Some come with a solution that you dip in the water to test for water hardness.

types of hardness testers

standard hardness test methods

Testing the hardness of steels can be used an indication of how easily they can be manipulated, (formed, machined etc.), and how they will perform mechanically. Hardness test methods Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid. Here’s how to perform a total hardness test using strips: 1. Dip a Strip Into Your Pool. Take a test strip from the container, being careful to only touch the white areas of the strip itself. Any accidental touches of the colored pads will compromise the .Hardness Testing Methods Rockwell Test Method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods.Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application.

самодельный влагомер воздуха

What is Brinell Hardness Test? In Brinell Hardness Test, an indenter, a ball made of carbide metal (formerly hardened steel) with diameter D, is pressed in the test object surface and the diameter ‘d’ of the indentation is measured followed the test object force removal.. Brinell hardness HB (according to standard HBW) is proportional to the quotient of the testing force . Each type of hardness test offers insights into different aspects of a material’s properties. Scratch hardness is more qualitative and useful for comparative analysis in geology and gemology. Indentation hardness provides quantitative data essential for engineering and manufacturing, while rebound hardness offers a non-destructive and quick . The Mohs hardness scale rates the hardness of minerals based on their ability to scratch softer ones. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field.

One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a Cooper coin (penny or 1,2.5 cents euro), a shard of glass, and a knife blade. You already have two of the tools required for the .

mohs hardness chart

Resultado da Resumo do jogo Boca Juniors vs. Monagas SC Conmebol Libertadores, placar final 4-0, de 29 de junho, 2023 em ESPN (BR).

tests for hardness|types of hardness testing methods